Do you wish you could make some changes to your lab layout? Maybe you can’t even imagine making changes because the cost of shutting down the lab and relocating staff is way beyond the budget. What if you could not only adjust the furniture and equipment locations, but also move the walls and plumbing valve locations in just a few hours? What if you could do this without reconfiguring the HVAC system at all? What if you could increase your electrical fixtures or add a new gas service without shutting down the lab? In today’s blog we will look at the future of laboratories: the HL-X-Lab media ceiling by the HLudi company. Here are the top 5 benefits to providing this type of mechanical system to your next laboratory. The future of lab design is here!

- ADAPTABILITY

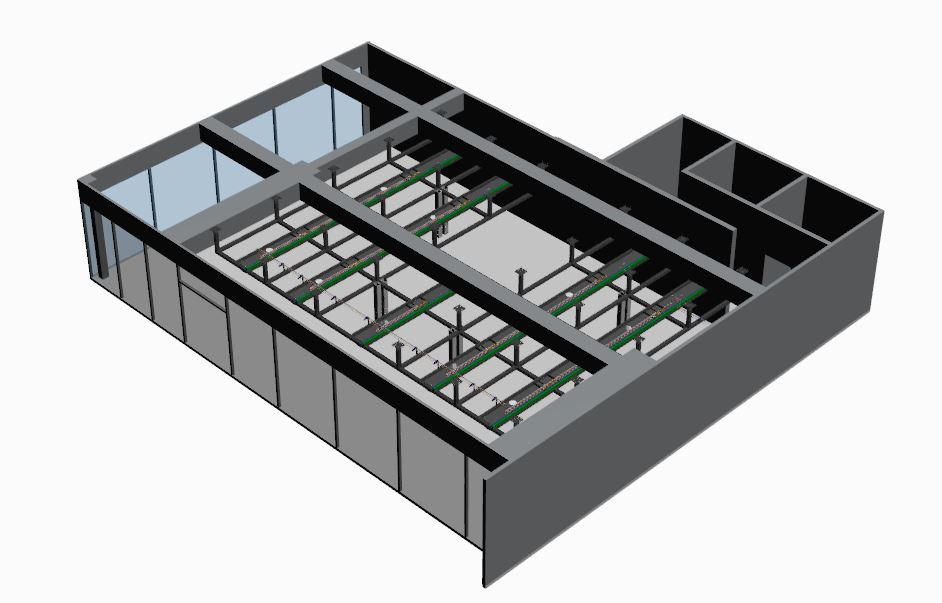

The adaptability of the media ceiling system is almost limitless. The repetitive aluminum grid is provided with lights, power, HVAC, data and plumbing services which quick connects along the “axis” at the center of each grid section. Technology such as self-closing plumbing valve connections, electrical busbars, ductwork speed clamps and local breaker switches allow services to be added, extended, and removed easily without shutting down the lab. Future mechanical changes can be made efficiently and effortlessly with minimal lab disruption.

Service columns hang from the grid, providing point of use for power, data and plumbing. The service columns can be moved anywhere along the grid, which means that your point of use is exactly where you need it. Additionally, the services in the columns are based on modules, and can easily be swapped or added onto when needed, and within an hour or so.

Extract air can also be taken from any point in the lab, meaning that your fume hoods and local exhaust arms (or snorkels) can be moved anywhere!

Wall panels can be constructed of glass or solid materials and can be used to reconfigure the space. Rooms can be completely set up, and if you change your mind, it is easy to reconfigure a new wall layout! The HVAC system or lighting does not need to be changed when setting up new wall locations.

- ENERGY SAVINGS

The media ceiling solution uses thermal layering to save energy- this allows the rising warmer air to be extracted well above the open grid, and the cool air is distributed below the grid. This adds greater efficiency and up to 30% energy savings, compared to cooling the traditional lab where the air is immediately mixed. Several other options are available to aid in the efficient heating and cooling of the space, including the addition of chilled beams, radiant waves, and incorporating grid zone heating and cooling.

With the media ceiling system, an additional amount of energy savings can be gained by using low face velocity fume hoods. The HL-X-Lab uses a unique and patented feature: the lens on the lab’s light works as the air diffuser for the lab space. There is a large surface area of perforated holes on the lens that allows the supply air into the room and eliminates cross drafts. This softly diffused air enters the room at about 5” to 7” per second, which is an environment that allows low face velocity (high performance) fume hoods to safely thrive and save significant energy.

- SPEED TO COMPLETION

The grid can be fully designed in a matter of days using a proprietary 3D software package. This design shows every component,  including screws and washers, if we want to zoom in on any detail. To make things easy for coordination, a 3D model can be provided to the architect and/or mechanical engineer. This shows limited (external) detail to keep the file size down and make it easier to work with. Once field dimensions are confirmed, the layout of the grid structure is designed and agreed upon through the submittal process. Once approved, a second submittal shows the incorporation of the mechanical systems into the grid structure, and includes all of the information for the other trades to make their limited connections. On most projects, the entire process from conception to completion can take about 14-16 weeks, depending of course on the size of the project and the length of the client’s decision making process.

including screws and washers, if we want to zoom in on any detail. To make things easy for coordination, a 3D model can be provided to the architect and/or mechanical engineer. This shows limited (external) detail to keep the file size down and make it easier to work with. Once field dimensions are confirmed, the layout of the grid structure is designed and agreed upon through the submittal process. Once approved, a second submittal shows the incorporation of the mechanical systems into the grid structure, and includes all of the information for the other trades to make their limited connections. On most projects, the entire process from conception to completion can take about 14-16 weeks, depending of course on the size of the project and the length of the client’s decision making process.

- SPEED OF INSTALLATION

Once approved and fabricated, field installation is fast. All of the mechanical systems have been simplified and factory precut. Also, most items have simple quick connection methods, such as speed clamps on the ductwork and quick connect self-closing plumbing valves.  Almost all of the assembly is done at chest height above the floor, limiting the repetition of ascending and descending the ladders. It also limits having to navigate ladders around the room and avoid other tradespeople on ladders, which improves safety on the jobsite. There are no issues of clashing and limited coordination with trades, as the complete design for the mechanical systems are done by one designer and manufactured to fit perfectly onsite. Once assembled, patented laser self-leveling synchronized jacks lift the media ceiling sections into place.

Almost all of the assembly is done at chest height above the floor, limiting the repetition of ascending and descending the ladders. It also limits having to navigate ladders around the room and avoid other tradespeople on ladders, which improves safety on the jobsite. There are no issues of clashing and limited coordination with trades, as the complete design for the mechanical systems are done by one designer and manufactured to fit perfectly onsite. Once assembled, patented laser self-leveling synchronized jacks lift the media ceiling sections into place.

- USER COMFORT

Finally, a lab without cross drafts! As discussed earlier, the same technology that allows the fume hoods to run at energy efficient face velocities also provides a great level of user comfort. All of the conditioned cooler supply air doesn’t present itself as a cold draft on the back of your neck- it is very well diffused into the space for a much more comfortable work environment.

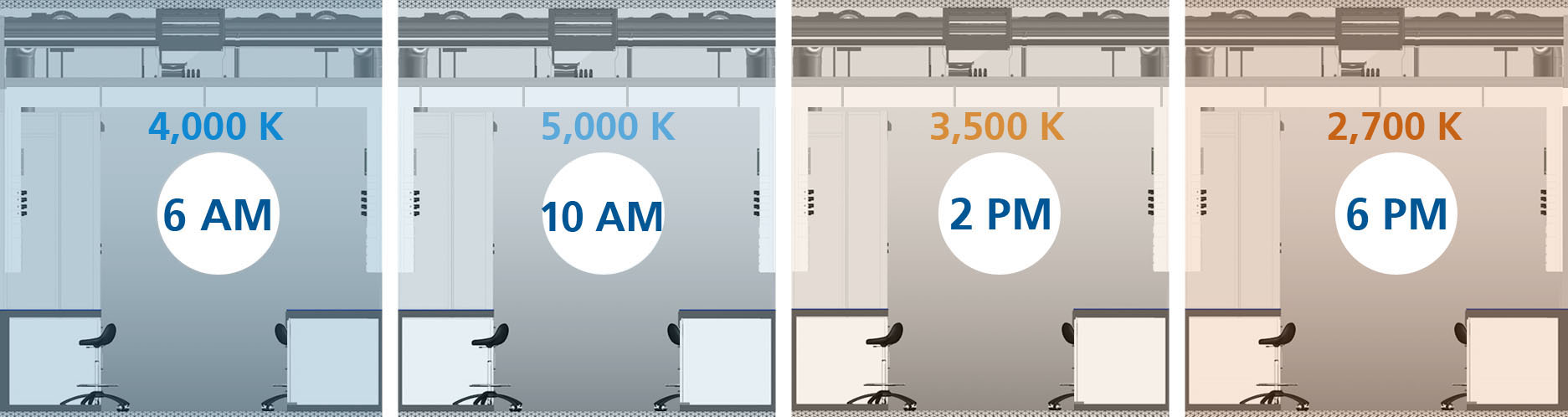

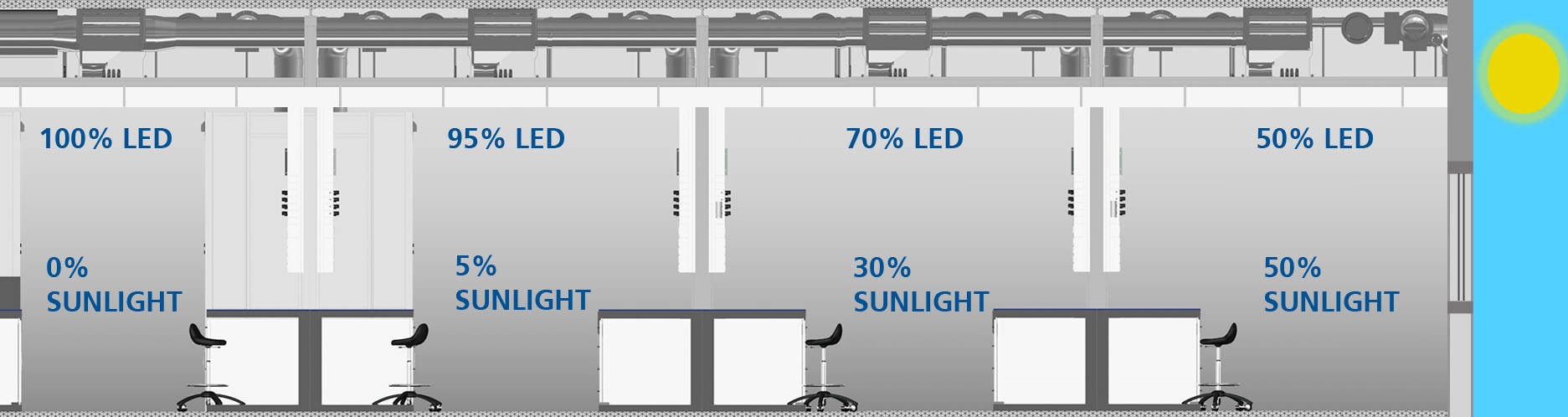

In addition to the air temperature quality, the HL-X-Lab LED lighting can be designed to be the most comfortable lighting available. Biodynamic lighting, which is a lighting management system that can mimic the quality and quantity of daylight, can improve our health and comfort- after all, our biological clocks are set by the color temperature and intensity of daylight! The HL-X-Lab lighting allows each luminaire in the building to be independently controlled to mimic the natural sunlight’s color temperature and intensity. Luminaires near windows on a sunny day would provide less intensity than the luminaires in areas of the lab where the sunlight does not reach. This helps to provide a consistent and comfortable lighting experience. Alternately, occupancy sensors can be used and programmed for even greater energy savings through dimming unoccupied areas on a per luminaire or per light channel strategy.

Figure 1 – This generic example shows how the lighting temperature and intensity could be programmed throughout the day to match the rhythm of the sun. This indoor ‘Biodynamic Light” is an available option that is said to set the body’s circadian rhythm, which brings health and comfort to the workforce.

Figure 2 – This generic example shows how individual light fixtures can be set up to sense the level of natural lighting and adjust intensity (and color temperature) accordingly throughout the space. This available option can limit hot spots, reduce eye strain and glare, and present a more comfortable and natural-feeling environment.

Figure 2 – This generic example shows how individual light fixtures can be set up to sense the level of natural lighting and adjust intensity (and color temperature) accordingly throughout the space. This available option can limit hot spots, reduce eye strain and glare, and present a more comfortable and natural-feeling environment.

These are just the top 5 of the many advantages of building your lab space with the flexibility of the HL-X-Lab media ceiling- there are lots of other benefits that could apply to your specific lab environment! If any of these concepts appeal to you, reach out to a New England Lab representative and make an appointment to see this technology in our Woburn, Massachusetts Showroom. Whatever your need, our goal is to make sure we offer a solution (or two) that meets it, and provide you with enough information to decide what’s best for your application. Contact us now!

Watch the 2:25 minute video on how the media ceiling gets installed!

copyright 2014, new england laboratory casework co., inc

copyright 2014, new england laboratory casework co., inc